Sheet metal working & cold rolling mills

Our brushes for sheet metal processing are mainly used for strip surface finishing, but also for deburring strip edges. Thanks to the expertise we have developed over decades in sheet metal processing in collaboration with renowned (cold) rolling mills, we offer comprehensive solutions for every application.

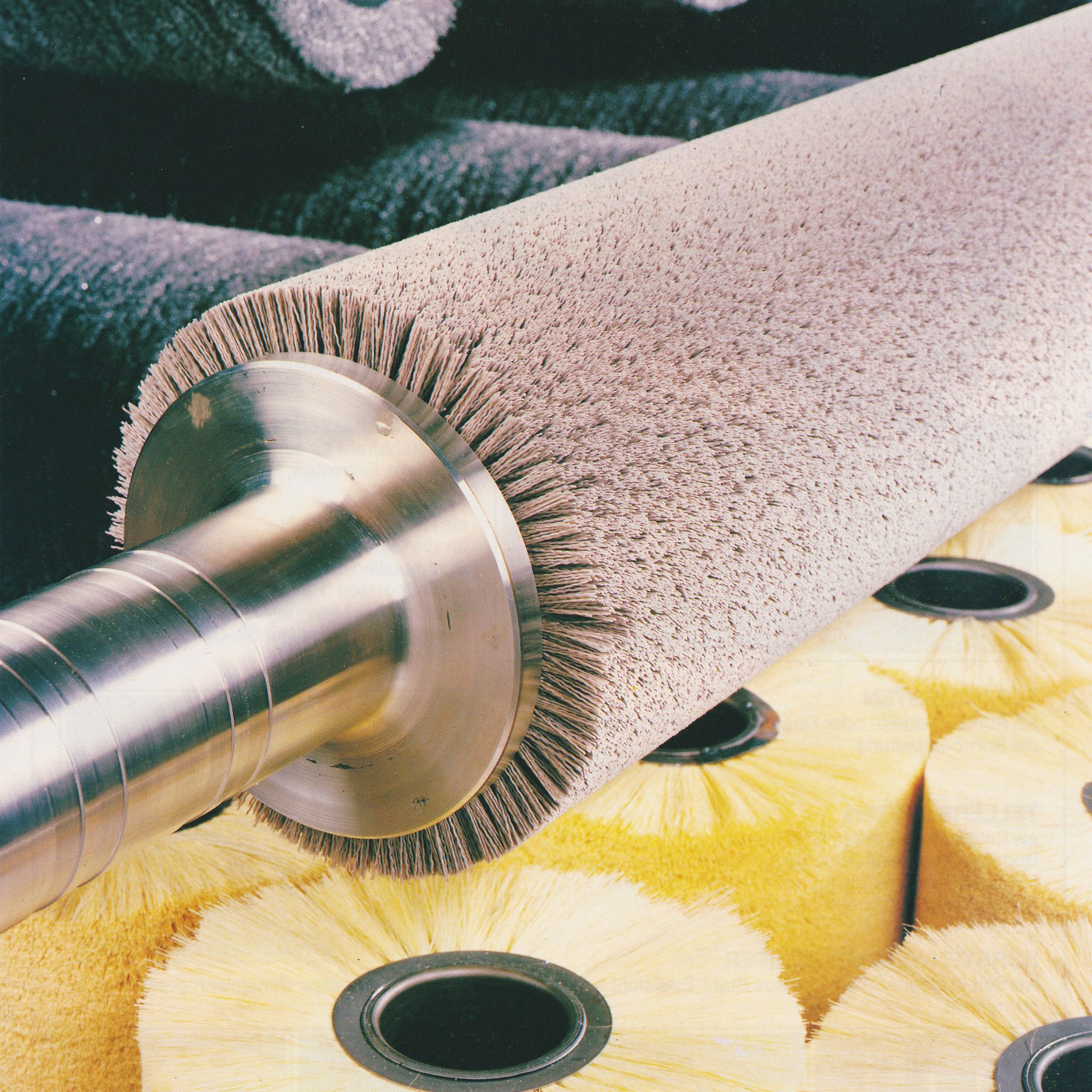

Technical brushes for steel strip processing

We carry out precise surface processing of hardened steel strips using specially developed roller brushes with wire trim. This technology ensures uniform and efficient polishing - even with high production requirements.

Industry-leading vertical integration for polishing brushes

Thanks to our own wire drawing and wire rolling facilities, Wahlmann-Bürsten has the greatest vertical integration in the field of industrial polishing brushes. This allows us to be exceptionally flexible and respond quickly to individual requirements and short-term changes.

Use of tested iron wires for maximum quality

In the manufacture of our industrial polishing brushes, we exclusively use high-quality, certified iron wires with a diameter of just 0.06 mm or more. This enables us to meet even the most stringent quality requirements in metalworking and steel finishing.

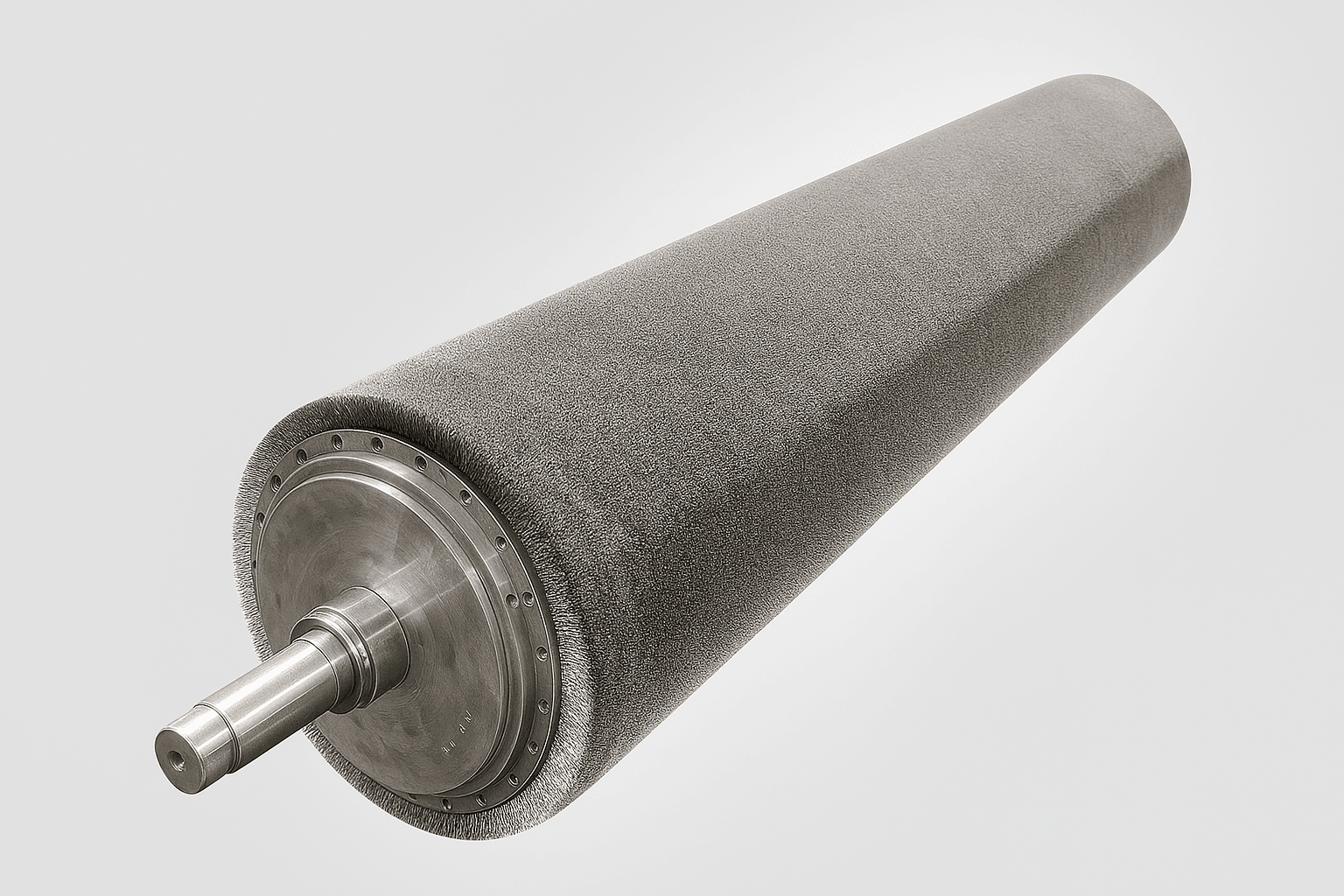

Perfect polishing results thanks to optimal brush design

Our polishing brushes are characterized by:

- high bristle density,

- precise bristle homogeneity,

- and brush surfaces that are sheared without any height variation.

These properties guarantee uniform and consistent polishing results - ideal for precise applications in strip finishing and steel strip processing.

Custom roller brushes for coarse and fine steel strips

Whether for coarse steel strips or particularly fine sheet metal surfaces - we supply the right roller brush for your requirements. Our goal is to work with you to develop the perfect solution for your desired strip surfaces.

Tailor-made solutions for your application

You can rely on our many years of experience in the manufacture of technical brushes for industry. We provide you with individual advice and supply you with the optimum polishing brushes and roller brushes for your steel strip production - quickly, reliably and in the highest quality.

Technical brushes for non-ferrous metal processing – precision for copper, brass and more

We offer customized technical brush solutions for the surface treatment of non-ferrous metals such as copper, brass, bronze and other non-ferrous metals. Our portfolio includes high-performance roller brushes with special abrasive grain trims for the effective, gentle and uniform processing of sensitive metal surfaces.

Abrasive grain trim with corundum - ideal for non-ferrous metals

Abrasive grain coating with corundum - ideal for non-ferrous metals

When processing non-ferrous metals, abrasive grain coatings with corundum components are primarily used. These enable controlled material removal and ensure a high-quality finished surface. Our brushes are ideal for industrial applications such as:

- Deburring

- Surface finishing

- Cleaning and structuring of non-ferrous metals

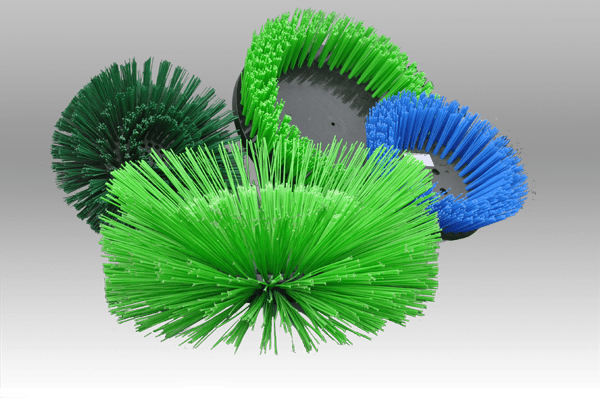

HEWALON brushes for precise results

Our roller brushes for non-ferrous metals are available in various outer diameters and working widths. For perfect adaptation to your application, we offer:

- HEWALON-A (aluminum oxide) for lighter surface finishing

- HEWALON-S (silicon carbide) for harder surface finishing

Both types of bristles are available in different grit sizes and bristle diameters and can be individually configured.

Individual adaptation according to belt surface result

In addition to our standard dimensions, we offer the option of precisely matching the abrasive grain fillings and brush properties to the desired belt surface result. Your requirements in terms of feel, gloss level, or structure of the non-ferrous metal surface are directly incorporated into the brush design.

Trim mixtures for maximum flexibility

Mixed bristles are indispensable, especially in non-ferrous metal surface processing. We work with you to develop the optimal bristle structure for your roller brush. We combine different abrasive grain materials and grit sizes in a homogeneous distribution with other bristles such as wires or natural fibers - for better results in the brushing process or longer service life.

Highest quality for copper, brass and alloys

Benefit from our many years of experience in the manufacture of technical brushes for non-ferrous metals. Whether copper sheets, brass plates, or other non-ferrous metal alloys - Wahlmann brushes stand for quality, durability and reproducible results in industrial metal processing.